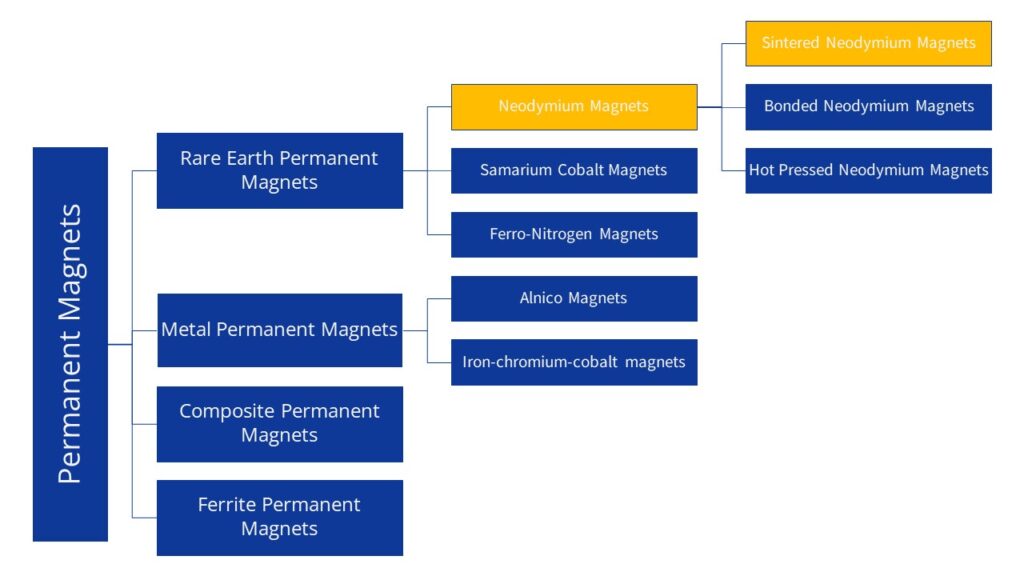

Metal magnetic materials are divided into two categories: permanent magnetic materials and soft magnetic materials.

- Usually the endowment coercivity greater than 0.8kA/m material called permanent magnetic material.

- The endowment coercivity less than 0.8kA/m material called soft magnetic material.

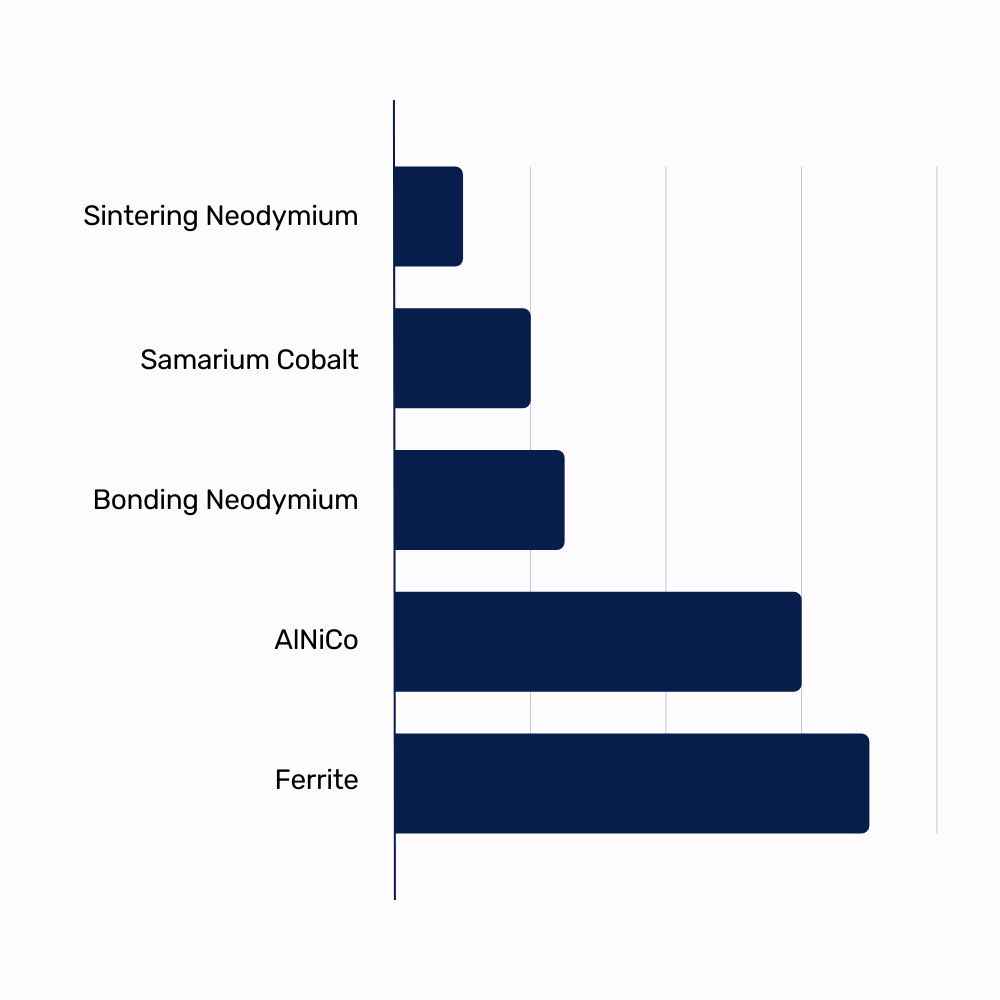

Several types of commonly used magnets magnetic force size comparison of magnetic force from large to small arranged as follows:

- Neodymium iron boron magnets > samarium cobalt magnets > alnico magnets > ferrite magnets

Attractable Metals

We know that magnets can attract iron.

The key principle is that a magnet will generate a magnetic field around it.

And magnetization will be present when the ferromagnetic object gets close to it, and it will generate another permanent magnet in that case.

Generally speaking, the metals that magnets can attract are relatively few and limited to ferromagnetic metals:

- Iron, cobalt, nickel, etc.

- Ferromagnetism refers to the magnetic state of a material that possesses spontaneous magnetization.

Many other metals – such as gold, copper, silver, lead, and tin – are not ferromagnetic.

Therefore, magnets cannot attract these metals.

Alnico Magnets

Alnico magnets are made by casting or sintering a combination of aluminum, nickel, and cobalt with iron and other elements. The resulting magnet has a high magnetic strength and temperature stability, making it ideal for applications that require a strong magnetic field in high-temperature environments.

Advantages

High Temperature Stability

Alnico magnets offer excellent temperature stability, making them suitable for high-temperature applications.

High Magnetic Strength

Alnico magnets have a high magnetic strength, making them suitable for applications that require a strong magnetic field.

Corrosion Resistance

Alnico magnets are resistant to corrosion, making them suitable for applications that require exposure to moisture or other corrosive elements.

Disadvantages of Alnico Magnets

Brittleness

Alnico magnets are brittle and can easily crack or break if exposed to high impacts.

Limited Shapes

Alnico magnets are limited in terms of the shapes and sizes that can be produced, making them less versatile than other types of magnets.

Cost

Alnico magnets are more expensive than other types of magnets, making them less cost-effective for some applications.

Alnico vs. Neodymium

Alnico magnets differ from neodymium magnets in several ways. While both types of magnets offer high magnetic strength, neodymium magnets are stronger and more versatile in terms of the shapes and sizes that can be produced. Additionally, neodymium magnets are less expensive than Alnico magnets, making them a more cost-effective option for some applications.

Ceramic Magnets

Ceramic magnets are made from a composite of iron oxide and barium or strontium carbonate.

These magnets are classified as permanent magnets, which means they retain their magnetic properties even when not in a magnetic field.

Ceramic magnets are known for their high resistance to demagnetization and their ability to maintain their magnetic properties at high temperatures.

Ceramic vs. Neodymium

Neodymium magnets are another type of permanent magnet that’s popular in the market. While they share some similarities with ceramic magnets, there are also significant differences between the two.

One of the main differences is their magnetic strength. Neodymium magnets are known for their exceptional magnetic strength, making them ideal for applications that require high performance. Ceramic magnets, on the other hand, have lower magnetic strength but offer better resistance to demagnetization and higher temperature tolerance.

Another significant difference is their cost. Ceramic magnets are generally less expensive than neodymium magnets, making them a more economical choice in some applications.

FeCrCo Magnets

FeCrCo magnets, also known as iron-chromium-cobalt magnets, are made from a composite of iron, chromium, and cobalt. These magnets are classified as permanent magnets, which means they retain their magnetic properties even when not in a magnetic field. FeCrCo magnets are known for their high magnetic strength, excellent temperature stability, and resistance to corrosion.

FeCrCo vs. Neodymium

Neodymium magnets are another type of permanent magnet that’s popular in the market. While they share some similarities with FeCrCo magnets, there are also significant differences between the two.

One of the main differences is their magnetic strength. Neodymium magnets are known for their exceptional magnetic strength, making them ideal for applications that require high performance. FeCrCo magnets, on the other hand, have lower magnetic strength but offer better temperature stability and corrosion resistance.

Another significant difference is their cost. FeCrCo magnets are generally more expensive than neodymium magnets, making them a less popular choice in some applications. However, the unique properties of FeCrCo magnets make them the preferred choice in specific industries such as aerospace, defense, and medical.

SmCo Magnets

SmCo magnets are made from samarium and cobalt, hence the name “SmCo.” These magnets are classified as rare earth magnets, which means they are made from rare earth elements such as samarium, neodymium, and dysprosium. SmCo magnets are known for their high magnetic strength, excellent temperature stability, and resistance to corrosion.

SmCo vs. Neodymium

Neodymium magnets are another type of rare earth magnet that’s popular in the market. While they share some similarities with SmCo magnets, there are also significant differences between the two.

One of the main differences is their magnetic strength. Neodymium magnets are known for their exceptional magnetic strength, making them ideal for applications that require high performance. SmCo magnets, on the other hand, have slightly lower magnetic strength but offer better temperature stability and corrosion resistance.

Another significant difference is their cost. SmCo magnets are generally more expensive than neodymium magnets, making them less popular in some applications. However, the unique properties of SmCo magnets make them the preferred choice in specific industries such as aerospace, defense, and medical.

Comparing the require material weight for generating the same magnetic strength.