Maintain excellent magnetic pull force across a spectrum of elevated temperatures.

These discs are the go-to solution for applications where standard magnets would fade.

Our heat-resistant neodymium disc magnets offer a graduated scale of thermal performance:

- H Grade (120°C): Entry-level heat resistance for moderately warm environments

- SH Grade (150°C): Ideal for automotive and industrial applications

- UH Grade (180°C): Perfect for demanding manufacturing processes

- EH Grade (200°C): Engineered for extreme industrial heat exposure

- AH Grade (220°C): Advanced thermal stability for specialized applications

- TH Grade (250°C): Ultimate heat resistance for the most severe thermal conditions

Heat Resistance Enhancement Process

1. Specialized alloy formulation with precise dysprosium and terbium additions

2. Optimized microstructure development during sintering

3. Controlled cooling to maximize coercivity at high temperatures

4. Rigorous thermal cycling tests to ensure performance stability

1. Grades and Thermal Performance

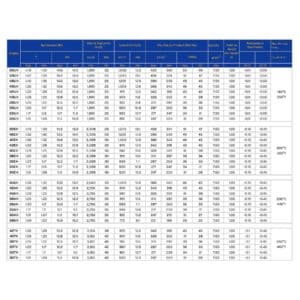

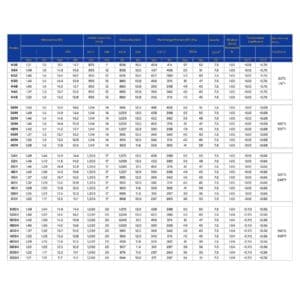

Available Grades: N35 to N54

Recommended Pairing:

- H & SH: N42 to N52 for optimal strength in moderate heat

- UH & EH: N38 to N45 for balanced performance in high heat

- AH & TH: N35 to N40 for maximum stability in extreme heat

2. Precision Disc Dimensions

Diameter Range:

- Minimum: 0.2mm (±0.05mm tolerance)

- Maximum: 300mm

- Thickness: Up to 60mm for magnetization

– Custom aspect ratios available to optimize thermal dissipation

3. Surface Enhancements

Standard:

- Nickel-Copper-Nickel (Ni-Cu-Ni) triple layer plating

Specialized thermal coatings:

- High-temp Zinc: Enhanced corrosion resistance up to 180°C

- Thermally Conductive Gold: Premium finish with heat dissipation properties

- Ceramic-infused Silver: High conductivity with thermal barrier properties

- Heat-Resistant PTFE: Non-stick and chemical-resistant up to 260°C

- Thermal Epoxy: Robust protection with insulating properties

- High-temp Parylene: Ultra-thin, uniform coating for precision high-heat applications

- Thermal Passivation: Bare metal treatment for maximum heat conductivity

4. Magnetization Configurations

Customize the magnetic orientation for your thermal environment:

- Axial: Standard for most heat-resistant applications

- Radial: Ideal for rotary high-temperature systems

- Diametric: Specialized orientation for unique thermal scenarios

5. Flexible Procurement

– No minimum order quantity

– From single prototype to high-volume production, tailored to your thermal testing needs

6. Thermal Quality Assurance

– RoHS 3 (2015/863/EU) compliant, including high-temperature scenarios

– REACH adherent, with consideration for thermal decomposition products

– CE marked for relevant high-temperature applications

– EMC tested across the full temperature range

– 100% thermal performance verification at rated temperatures

7. Thermally Considerate Packaging

– Heat-resistant vacuum-sealed bags for bulk orders

– Individual high-temp resistant packaging for discs over 50mm

– Thermal-shock protective cases available for sensitive shipments

Applications

Our Heat Resistant Neodymium Disc Magnets excel in:

- High-temperature industrial automation

- Automotive underhood components

- Aerospace and turbine systems

- Thermal processing equipment

- High-temp sensors and actuators

- Geothermal and solar energy systems

- Heat-resistant consumer electronics

The Heat Resistant Advantage

- Thermal Stability: Maintain magnetic properties at elevated temperatures

- Performance Predictability: Engineered for consistent force across temperature ranges

- Extended Lifespan: Resist thermal demagnetization in hot environments

- Versatile Integration: Suitable for a wide range of high-temp applications

- Energy Efficiency: Optimize magnetic systems in thermally challenging conditions

- Safety Assurance: Reliable magnetic performance in safety-critical hot zones

Whether you’re designing for the heat of an engine compartment, the intensity of industrial furnaces.

Or the consistent warmth of energy systems.

Our team is ready to help you select the perfect thermal grade.

Contact our specialized heat-resistant magnet engineers today.

Let us discuss how we can tailor these thermally robust magnets.

Make them fit your exact specifications and temperature requirements!

Reviews

There are no reviews yet.