Harness the power of advanced magnetic technology with our passivated sintered neodymium tube magnets.

These hollow cylindrical marvels combine the strength of rare-earth magnets with the corrosion resistance of passivation.

They offer unparalleled performance in challenging environments.

Passivation: The Key to Longevity

Our tube magnets undergo a specialized passivation process, setting them apart in durability and versatility:

- Chemical Resistance: A thin, protective oxide layer shields against corrosive elements

- Bare Metal Aesthetics: Maintains the natural appearance of neodymium

- Enhanced Longevity: Significantly extends the magnet’s lifespan in harsh conditions

- Improved Stability: Reduces surface reactivity for consistent performance over time

- Environmentally Friendly: No additional plating materials required

Passivation Process:

1. Surface cleaning and preparation

2. Controlled oxidation in a carefully managed chemical bath

3. Formation of a nanoscale protective layer

4. Quality inspection to ensure uniform coverage

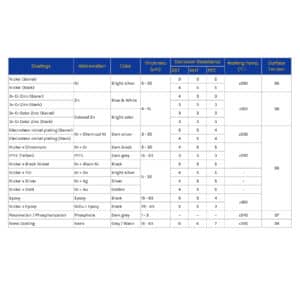

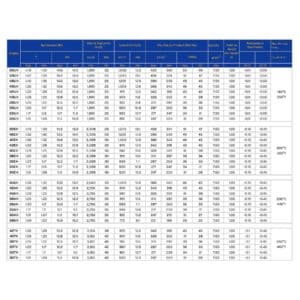

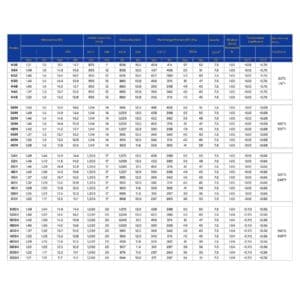

1. Magnetic Grades

Standard Grades: N35 to N54

- Recommended for passivated magnets: N42 to N52 for optimal strength-to-corrosion resistance ratio

Temperature Grades:

- Standard (80°C)

- H (120°C), SH (150°C), UH (180°C)

- EH (200°C), AH (220°C), TH (250°C) for extreme environments

2. Precision Dimensions

Outer Diameter:

- Minimum: 0.2mm (±0.05mm tolerance)

- Maximum: 300mm

– Inner Diameter: Customizable to your specifications

– Length: Up to 60mm for magnetized sections

– Wall Thickness: Tailored to your strength requirements

3. Magnetization Configurations

– Axial: Magnetic field parallel to the tube’s length (standard)

– Radial: Magnetic field perpendicular to the tube’s axis

– Diametric: Poles across the diameter (for larger tubes)

4. Flexible Ordering

– No minimum order quantity

– From single prototypes to large-scale production

5. Rigorous Quality Standards

– RoHS compliant: Free from restricted substances

– REACH adherent: Environmentally and health-conscious

– CE marked: Meeting European safety standards

– EMC tested: Ensuring electromagnetic compatibility

6. Specialized Packaging

– Vacuum-sealed bags for bulk orders

– Individual packaging for tubes over 50mm in diameter

– Custom packaging solutions available for sensitive applications

Applications Unleashed

Passivated Neodymium Tube Magnets excel in:

- Chemical processing equipment

- Marine and offshore installations

- High-humidity environments

- Magnetic separation systems

- Flow control devices

- Sensor arrays in corrosive settings

- Experimental physics apparatus

The Passivated Tube Magnet Advantage

- Corrosion Resistance: Withstands challenging chemical and atmospheric conditions

- Bare Metal Conductivity: Ideal for applications requiring electrical or thermal conductivity

- Hollow Design: Allows for mounting on shafts or passage of materials through the center

- Customizable Field Patterns: Unique magnetic configurations possible with tube geometry

- Weight Reduction: Lighter than solid cylinders while maintaining edge field strength

- Thermal Management: Improved heat dissipation compared to solid magnets

Whether you’re designing for harsh environments, need specific magnetic field configurations.

Or require the unique properties of tubular magnets, our team is ready to help you optimize your design.

Contact our magnet engineering specialists today.

Let us discuss how we can tailor these innovative magnets to your exact specifications.

Reviews

There are no reviews yet.