Magnet Properties

Neodymium magnets are composed primarily of neodymium (Nd), iron (Fe), and boron (B).

The grade of neodymium you can pick:

- Entry level: N35 – N42 (You get outstanding strength per dollar spent)

- Demanding: N44 – N48

- Extreme: N50 – N54 (The highest magnetism to size ratio)

If you are not sure which grade will be the best for your application, talk to Osenc.

You will receive expert tips within just a few hours.

Lead Time

The estimated lead time for manufacturing magnets after your order confirmation.

- 7 days for regular shapes, convenient for quick delivery

- 20 days for custom designs with complex geometries or specific requirements

As a custom neodymium magnet supplier, we can offer:

- Large-diameter strong magnetic rings up to 300 mm wide

- And tiny magnetic rings with diameters as small as 1.5mm

Available Dimensions

Any custom sizes within the range are available upon request.

Just give us some basic dimensional information for cost estimation.

1). Dimensional ranges for neodymium ring magnets

- Outer diameters: 1.5 – 300 mm (1/16 – 11 13/16 inches)

- Inner diameters: 0.4 – 250 mm (1/64 – 9 27/32 inches)

- Height: 0.3 – 120 mm (1/64 – 4 ¾ inches)

- Magnetic direction: 100mm (3 15/16 inches)

Note:

If your designs are close to the biggest or smallest values, we need to confirm details case by case.

2). The largest ring neodymium magnets

- Outer diameter 250mm – inner diameter 220mm × height 60mm (4 ¾ – 3 1/8 x 2 3/8 inches)

- Outer diameter 80mm – inner diameter 50mm × height 120mm (3 1/8 – 1 15/16 x 4 ¾ inches)

3). The smallest ring neodymium magnets

- Outer diameter 1.5mm – inner diameter 0.4mm × height 0.3mm (1/16 – 1/64 x 1/64 inches)

Dimensional Identifications

Below is the dimensional identification for circular neodymium magnets.

- D for the outer diameter

- d for the inner diameter

- H for the thickness (height)

If a ring / circular neodymium magnet has a dimension of D10 x d7 x 3 mm

- Its outer diameter is 10 mm

- The inner diameter is 7 mm

- The thickness is 3 mm

Tolerance

Manufacturing tolerance for dimensions.

Holes

Meanwhile, ring neodymium magnets have 2 types of holes:

- Straight holes: drilled vertically into the magnets

- Countersunk holes: Also called screw holes, includING a primary hole and a major hole

For ring or circular neodymium magnets with a countersunk hole

- D for the outer diameter

- M for the diameter of the major hole

If a ring magnet has a dimension of D10 x M7 x 2 mm

- Its outer diameter is 10 mm

- The major hole diameter is 7 mm

- And the thickness is 2 mm

Besides indicating the sizes, it’s always good to include the countersunk angle.

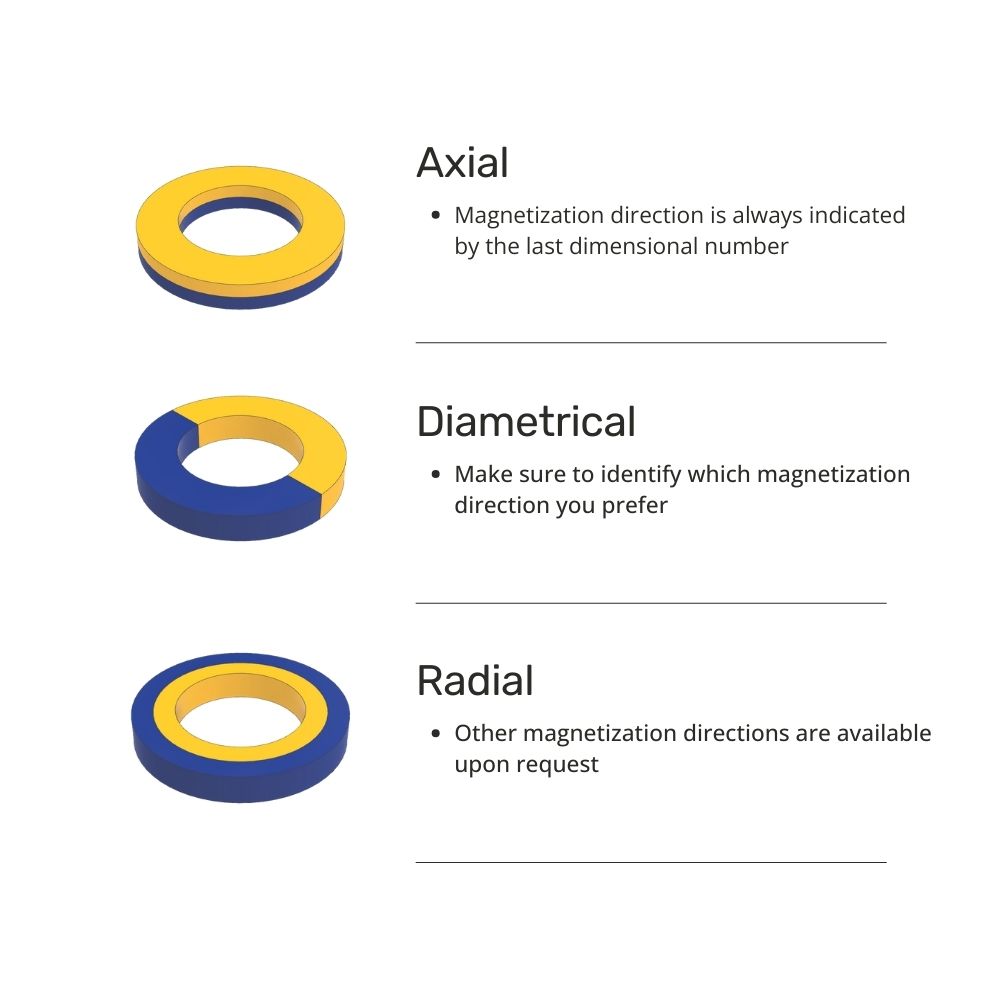

Magnetization Directions

Ring magnets can be axially magnetized or radially magnetized.

- Axially magnetized ring magnets have north and south poles on the 2 planes.

- Radially magnetized ring magnets have north and south poles on the circular side.

Surface Treatments

Generally speaking, Osenc can apply multiple types of protective layers to your magnets, depending on the applications.

- Cost effective platings: Zinc, Nickel, Epoxy

- Performance coatings: Parylene, PTFE, nano

You can directly indicate the type of coating used (e.g., nickel, zinc, epoxy) for protection against corrosion.

Or, simply tell us your applications and expectations.

Temperature Rating

Mention the maximum operating temperature the magnet can withstand without losing its magnetic properties.

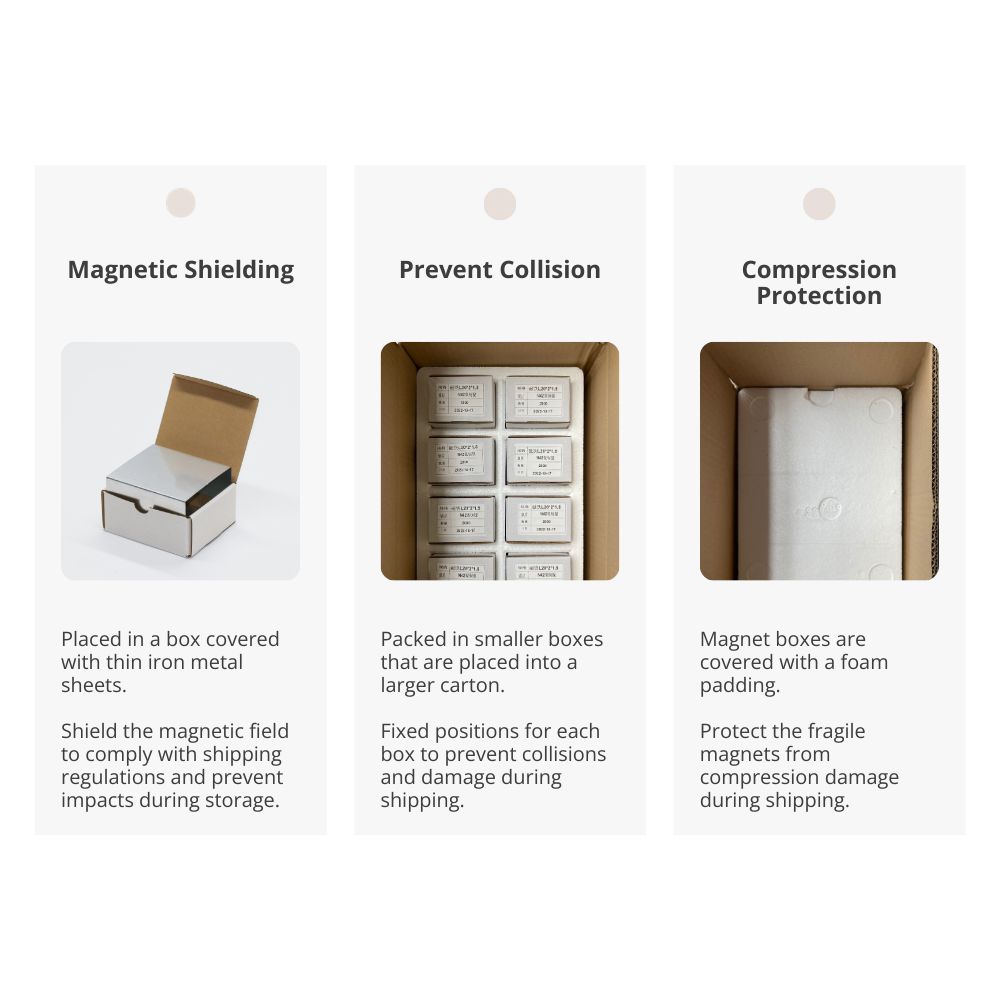

Packaging

We will ship your neodymium magnets packed in the way as illustrated below to ensure their safety and integrity.

This packing method offers optimal protection for custom strong magnets with common dimensions.

We’ve verified this packing method with simulated drop tests and compressing tests in our lab.

- Meanwhile, different packing methods available upon request.

- And, there are different ways to pack larger neodymium magnets with super strong pull force.

Technical Documentation

Offer links or downloads for technical datasheets, magnetization graphs, and other relevant documentation.

Quality Inspections

We apply quality inspections to your neodymium magnets before shipment.

Apply partial inspection to regular magnets, randomly picking 10% of the packed magnets.

Quality inspection tasks include magnetic properties, and other aspects as these listed examples:

- Check magnetic strength and direction, using magnetic field viewing films and magnetic bars, AQL = 1.5, C = 0

- Measure dimensional tolerances and deviations, using tools like calibers and thickness micrometer, AQL = 1.5, C = 0

- Verify magnetic flux density and surface field strength, by picking 10 pieces randomly

- Visual inspection ensures no defects in appearance, AQL = 1.0, C = 0

The warranty policy for the magnets, including any guarantees against defects.

Shipping and Return Policies

Clearly outline shipping options, costs, and return policies for customers’ reference.

Customer Support

Provide contact information for customer inquiries and support related to the product.