These top-tier magnets represent the peak pull force of rare-earth magnetic technology.

They offer unparalleled performance for the most demanding applications.

Our highest-grade neodymium disc magnets push the boundaries of magnetic performance:

– N50: The gateway to elite magnetic power

- Typical Br (Residual Flux Density): 13.9-14.4 kG

- Ideal for: High-performance motors, advanced sensors

– N52: The penultimate grade in widespread production

- Typical Br: 14.2-14.6 kG

- Perfect for: Cutting-edge medical equipment, aerospace applications

– N54: The absolute pinnacle of commercial neodymium magnets

- Typical Br: 14.5-14.9 kG

- Designed for: Bleeding-edge research, ultimate-performance devices

The Summit of Sintering

1. Ultra-pure neodymium alloy preparation

2. Precision particle alignment for maximum magnetic saturation

3. Advanced sintering techniques to achieve ultimate material density

4. Specialized heat treatment to optimize magnetic domains

5. Rigorous quality control to ensure top-tier performance

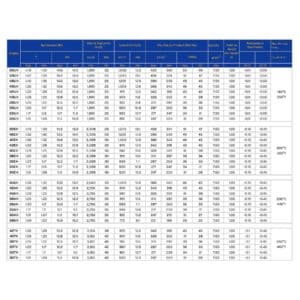

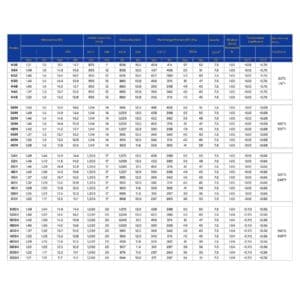

1. Grade Selection

Choose from N50, N52, or N54 based on your specific strength requirements

Temperature Grades Available:

- Standard (80°C)

- H (120°C), SH (150°C), UH (180°C)

- EH (200°C), AH (220°C), TH (240°C) for extreme environments

(Note: Higher temperature grades may slightly reduce maximum magnetic strength)

2. Precision Disc Dimensions

Diameter Range:

- Minimum: Diameter 0.2mm (±0.05mm tolerance)

- Maximum: Diameter 300mm

- Thickness: Up to 60mm for magnetization possibility

– Aspect ratio optimization available for maximum magnetic flux

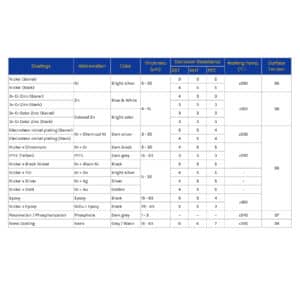

3. Surface Enhancements

Standard:

- High-performance Nickel-Copper-Nickel (Ni-Cu-Ni) triple layer plating

Premium finish options:

- Zinc plating: Superior corrosion resistance

- 24K plating: Luxurious appearance with excellent conductivity

- Silver plating: Enhanced electrical and thermal properties

- Black Nickel: Sleek, modern aesthetic

- PTFE coating: Ultra-low friction, chemical-resistant barrier

- Epoxy coating: Extreme durability and impact resistance

- Parylene coating: Ultra-thin, pinhole-free conformal coating

- Passivation: Engineered for maximum corrosion resistance without dimensional change

4. Magnetization Directions

Tailor the magnetic field orientation:

- Axial (Through thickness): Standard for most disc applications

- Diametric: Magnetic poles across the diameter for specialized uses

5. Quantity Flexibility

– Zero minimum order quantity

– From single prototype to mass production of elite-grade magnets

6. Quality Assurance

– RoHS compliant

– REACH adherent

– CE marked

– EMC tested

– 100% individual magnet flux density verification

7. Protective Packaging

– Military-grade vacuum-sealed bags for bulk orders

– Individual high-security packaging for discs over 50mm

– Custom packaging solutions for sensitive or classified projects

Applications

Our N50, N52, and N54 Neodymium Disc Magnets excel in:

- Quantum computing components

- Next-generation MRI machines

- Particle accelerator systems

- Space exploration equipment

- Advanced maglev transportation

- Cutting-edge green energy systems

- Ultra-sensitive scientific instruments

The Ultra-High Grade Advantages

- Unprecedented Strength: Maximum magnetic force in minimal space

- Efficiency Redefined: Achieve more with less material

- Miniaturization Enabler: Powerful magnetic fields from incredibly small sources

- Performance Consistency: Engineered for reliability at the highest levels

- Future-Proof Technology: Stay ahead with the strongest magnets commercially available

- Research Ready: Ideal for pushing the boundaries of magnetic applications

Whether you’re developing next-generation technologies, conducting cutting-edge research.

Or creating the most efficient devices possible.

Our team is ready to provide you with the ultimate in magnetic performance.

Connect with our elite-grade magnet specialists today.

Reviews

There are no reviews yet.