These precision-engineered arc magnets combine the superior strength of neodymium with a uniquely curved geometry.

Open up a world of possibilities for rotational and radial applications.

Our segmental arc magnets offer a distinctive edge in magnetic solutions:

- Seamless Circular Integration: Perfect for creating complete ring assemblies

- Optimized Magnetic Flux: Curved shape allows for ideal field distribution in rotary systems

- Space Efficiency: Maximizes magnetic material in circular housings

- Customizable Arc Lengths: Tailor the sweep angle to your exact specifications

- Smooth Rotational Performance: Ideal for motors and generators

- Stackable Design: Create multi-layer magnetic systems with ease

Precision Sintering for Perfect Arcs:

1. Custom mold creation for exact arc specifications

2. High-purity neodymium alloy preparation

3. Specialized sintering process to achieve uniform density across the arc

4. Precision grinding and machining to ensure perfect fit and finish

5. Magnetization along the optimal axis for arc performance

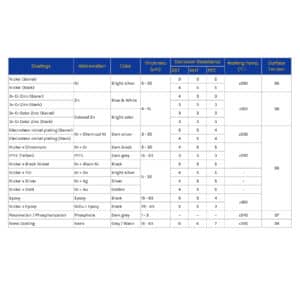

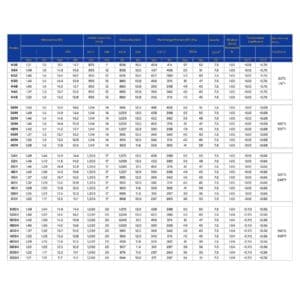

1. Magnetic Grades

Available Grades:

- N35 to N54

Recommended for Arcs:

- N42 to N52 for optimal balance of strength and machinability

Temperature Grades:

- Standard (80°C)

- H (120°C), SH (150°C), UH (180°C)

- EH (200°C), AH (220°C), TH (240°C) for high-temp applications

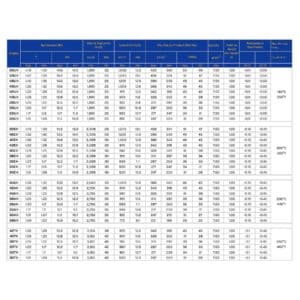

2. Arc Dimensions

- Outer Radius: From 1mm to 150mm

- Inner Radius: Customizable based on application requirements

- Arc Length: From 15° to 180° sweep angles

- Thickness: Up to 60mm

Tolerance: As precise as ±0.05mm for critical dimensions

3. Surface Enhancements

Standard:

- Nickel-Copper-Nickel (Ni-Cu-Ni) triple layer plating

Specialized arc-friendly finishes:

- Zinc plating: Uniform protection following the arc contour

- Gold plating: Luxurious finish with excellent conductivity

- Silver plating: Enhanced thermal and electrical properties

- Black Nickel: Sleek, modern aesthetic

- PTFE coating: Non-stick, chemical-resistant barrier that flexes with the arc

- Epoxy coating: Robust protection for harsh environments

- Parylene coating: Ultra-thin, uniform coating for tight tolerances

- Passivation: Bare metal treatment for specific requirements

4. Magnetization Directions

Tailor the magnetic orientation to your arc design:

- Radial: Magnetic field follows the curve of the arc (most common)

- Axial: Magnetic poles on the flat faces of the arc

- Diametric: Poles across the thickness of the arc segment

5. Flexible Arc Procurement

– No minimum order quantity

– From single prototype arcs to full circular array production

6. Quality Assurance

– RoHS compliant

– REACH adherent

– CE marked

– EMC tested

– 100% arc geometry and magnetic field verification

7. Protective Packaging

– Custom-molded trays to secure arc segments

– Vacuum-sealed packaging for long-term storage

– Individual packaging for larger arc segments

Applications

Our Sintered Neodymium Segmental Arc Magnets excel in:

- High-efficiency electric motors

- Precision rotary encoders

- Wind turbine generators

- Magnetic bearing systems

- Curved linear motors

- Specialized MRI equipment

- Unique magnetic couplings and clutches

Segmental Arc Advantages

- Shape-Specific Strength: Magnetic field optimized for circular and rotational systems

- Assembly Simplicity: Easy integration into ring-shaped structures

- Customizable Curvature: Tailor the arc to your exact circular requirements

- Compact Power: Maximize magnetic force in ring-shaped spaces

- Rotational Symmetry: Achieve perfect balance in spinning applications

- Scalable Solutions: From tiny precision instruments to massive industrial machines

Whether you’re designing the next generation of electric motors, creating ultra-precise rotary sensors.

Or developing revolutionary circular magnetic systems.

Our team is ready to help you harness the power of the arc.

Connect with our specialized arc magnet engineers today!

Reviews

There are no reviews yet.