Are you wondering what magnetic flux density is?

Then you’ve come to the right place.

Today, we’ll dive deep into the concept of magnetic flux density.

We’ll explore its definition, measurement techniques, and practical applications in various fields.

So, let’s get started!

What is Magnetic Flux Density?

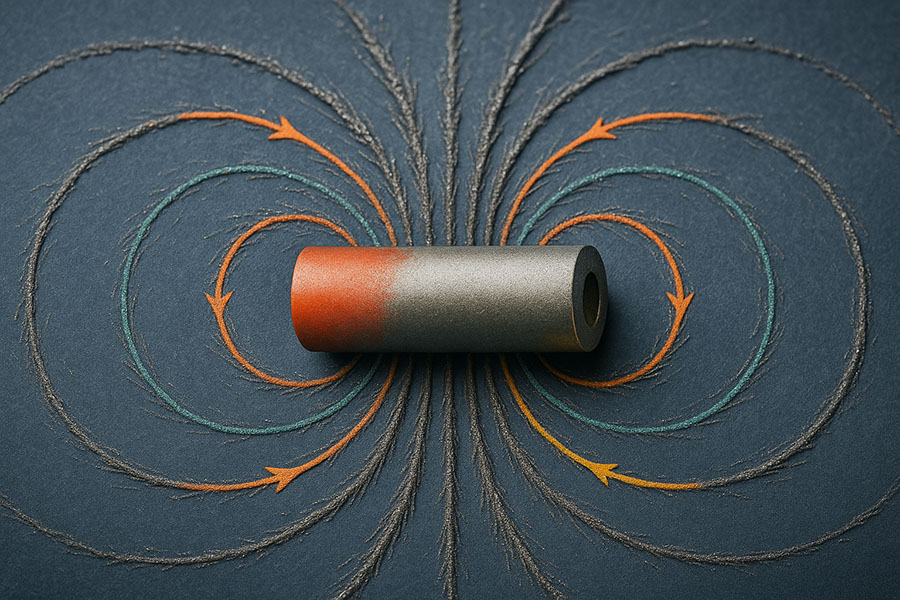

At its core, magnetic flux density is a vector quantity.

- It represents the magnitude and direction of the force experienced by a moving electric charge in a magnetic field.

- We symbolize it by the letter “B”.

And it’s defined as the force acting per unit current per unit length on a wire placed perpendicular to the magnetic field.

Here are some key points to keep in mind:

- The SI unit of magnetic flux density is the tesla (T).

- While the CGS unit is the gauss (G).

Magnetic flux density is related to the total magnetic flux Φ passing through a surface.

- The equation is Φ = B⋅A = BA cos θ.

- Where A is the area of the surface.

- And θ is the angle between the magnetic field lines and the normal to the surface.

In a uniform magnetic field, the flux density is simply the magnitude of the field.

However, in a non-uniform field, it varies in both magnitude and direction at different points.

Why Should You Care?

Understanding magnetic flux density is crucial for anyone working with or studying magnetic fields.

- It’s a fundamental quantity that helps us quantify the strength and orientation of magnetic fields.

- This is essential for designing and optimizing various electromagnetic devices and systems.

Measuring Magnetic Flux Density

Now that we know what magnetic flux density is, let’s explore how it’s measured in practical applications.

There are several methods and instruments commonly used.

Each has its own advantages and is suitable for different field strengths and applications.

Hall Effect Sensors/Probes

Hall effect sensors convert magnetic fields into electrical signals.

They do this by developing a voltage across a current-carrying conductor perpendicular to the field.

These probes can be axial (sensitive along the probe axis) or transverse (sensitive perpendicular to the probe).

They are often used in gaussmeters for measuring fields above 1 mT.

Fluxmeters with Search Coils

Fluxmeters use a conductor loop or coil to identify the perpendicular magnetic flux.

The measurement depends on the coil size.

Moving the coil in the field induces a voltage proportional to the flux.

These devices are commonly used with Helmholtz coils to measure total flux and permeability.

Magnetoresistive Sensors

Magnetoresistive sensors measure the change in electrical resistance of a material in a magnetic field.

They can be used in both magnetometers (for low fields) and gaussmeters (for high fields).

Magnetometers

Magnetometers are used for measuring very low magnetic fields (<1 mT).

There are various types, including:

- Proton precession (using hydrogenous liquids)

- Optically pumped (using polarized alkali gases)

- SQUID (superconducting loops)

- Fluxgate (measuring field gradient along a rod)

Permeability Meters

Permeability meters measure how easily a material can be magnetized.

This is an important parameter for stainless steels.

Values range from 1 (vacuum) to 2.

Advantages of Electrochemical Methods for Measurement

Using an electrochemical method to measure magnetic flux density offers several advantages:

Simplicity and convenience

The method allows measuring MFD using just a voltmeter to detect the change in open circuit potential.

Without needing a dedicated tesla meter or magnetometer.

High sensitivity

The proposed electrochemical method can detect about a 2% change in MFD in the range of 0.05 T to 0.5 T.

With a 1 mV increase in potential change corresponding to a 16-28% increase in MFD, depending on the solution.

Wide measurement range

The method has been validated for measuring MFD from 0.05 T to 0.5 T.

Covering a practically useful range for many applications.

Potential for miniaturization and integration

Electrochemical sensors can be made small and integrated with other systems.

Allowing for compact, embedded MFD sensors.

Insight into magnetic field effects on electrochemistry

This method provides a way to study how magnetic fields influence electrochemical processes like corrosion, electrocatalysis, and mass transport.

This is valuable for magnetoelectrochemistry research and applications.

Practical Applications of Magnetic Flux Density

Magnetic flux density finds numerous practical uses and applications across various fields of technology.

Let’s explore some of the most prominent ones:

Electrical Engineering & Electromechanics

Rotating magnetic fields are used in electric motors and generators.

The interaction of magnetic fields in transformers is conceptualized as magnetic circuits.

Measuring and Sensing

The Hall effect is where a voltage is generated perpendicular to an applied magnetic field.

- It is often used to measure the magnitude of magnetic fields.

- And determine the sign of charge carriers in semiconductors.

Shielding and Field Shaping

Magnetic flux controllers are made of soft magnetic materials like steel laminations, ferrites, and magnetic composites.

They are used to concentrate, redistribute, or shield magnetic fields in induction heating systems.

This improves heat patterns and prevents unintended heating.

Energy Storage

The energy needed to generate a magnetic field is stored in the field itself for linear non-dispersive materials.

And it is released when the field is destroyed.

Inductors store energy in their magnetic fields.

It is equal to the work required to establish the current through the inductor.

Magnetic Coupling and Actuation

Magnetorheological fluids are used as controllable frictional couplings.

The fluid’s viscosity changes with applied magnetic field.

This allows magnetic actuation of mechanical systems.

- Increasing flux density can improve the efficiency and performance of these MR fluid devices.

Navigation

The Earth’s magnetic field is important for navigation using a compass.

Magnetic Flux Density and Electromagnetic Induction

Magnetic flux density is fundamentally related to electromagnetic induction.

This is described by Faraday’s law.

Here’s how they’re connected:

A changing magnetic flux induces an electromotive force (EMF) in a conductor.

- The induced EMF is proportional to the rate of change of magnetic flux dΦ/dt.

Since magnetic flux depends on flux density B, the induced EMF can be expressed in terms of the rate of change of B.

- EMF = -N dΦ/dt = -N A dB/dt.

- Where N is the number of turns in the coil and A is the area.

Practical applications like generators and transformers rely on changing magnetic fields and flux densities.

- They induce EMFs and currents.

Eddy currents are induced circulating currents in conductors exposed to changing magnetic fields.

- They also result from changing flux densities and create opposing magnetic fields (Lenz’s law).

Magnetic Flux Density in Electric Motor Design

Magnetic flux density plays a crucial role in various aspects of electric motor design, such as:

Torque production

The interaction between the magnetic fields of the rotor and stator generates torque.

This allows the motor to convert electrical power into mechanical power.

Iron core utilization

Analyzing the flux density distribution helps determine if the iron core is being used optimally.

It identifies regions of saturation or underutilization.

Calculating losses

Both iron losses (eddy current and hysteresis losses) and copper losses (ohmic losses) depend on the magnetic flux density.

This influences motor efficiency.

Winding configuration

The winding pattern of the stator coils is designed based on the desired magnetic flux density distribution.

Material selection

The choice of magnetic materials is based on their ability to provide the required magnetic flux density for the application.

- Such as permanent magnets and soft magnetic composites (SMCs)

Acoustic noise and vibration

The spatial and temporal distribution of magnetic flux density in the air gap determines the electromagnetic forces acting on the motor structure.

This affects noise and vibration characteristics.

Magnetic Flux Density and Transformer Efficiency

Magnetic flux density plays a critical role in transformer efficiency in several ways:

Core saturation

The flux density must be kept below the saturation level of the core material.

This avoids increased losses and reduced efficiency.

Core losses

Hysteresis and eddy current losses in the core depend on the flux density and the core material properties.

Proper material selection and lamination help minimize these losses.

Operating flux density selection

The choice of operating flux density balances efficiency, size, and cost for the specific application and frequency.

Winding losses

While not directly related to flux density, proper conductor sizing and minimizing winding resistance are important for overall efficiency.

Nonlinear loads and harmonics

Nonlinear loads can introduce harmonic frequencies that increase core losses and distort the flux density waveform.

- This reduces efficiency.

- K-factor rated transformers are designed to handle harmonics better.

Magnetic Flux Density in MRI

Magnetic flux density affects the performance of MRI machines in several key aspects:

Signal-to-noise ratio (SNR) and spatial resolution

Higher magnetic field strengths result in higher flux density.

This leads to improved SNR and spatial resolution for clearer and more detailed images.

Image artifacts

Inhomogeneities in the main magnetic field and susceptibility variations can create various artifacts.

This is especially true at higher field strengths.

RF heating and specific absorption rate (SAR)

The amount of RF energy deposited in tissues depends on the strength of the radiofrequency field.

It varies between MRI systems.

Nerve stimulation

Rapidly switching magnetic field gradients can induce electric fields that cause nerve stimulation.

So limits are set on the rate of change of magnetic fields (dB/dt).

Implanted medical devices

Strong magnetic fields can cause issues with implanted devices.

This requires MR-conditional devices to be tested and labeled for specific flux density limits.

Acoustic noise

The vibration of gradient coils due to rapid switching causes loud acoustic noise.

This increases with field strength and requires hearing protection.

Wrapping Up

Well, there you have it!

We’ve covered a lot of ground in this comprehensive guide to magnetic flux density.

From its fundamental definition and measurement techniques to its practical applications in various fields.

Hope you now have a deeper understanding and appreciation for this important concept.

And if you have need premium magnets, don’t hesitate to reach out.